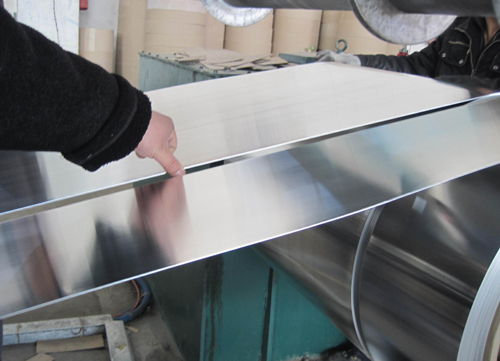

Aluminium strip for transformer

Aluminium strip for transformer is the key raw material for the manufacture of transformer windings, it is made by rolling and cutting of smelting aluminum ingot. As aluminum strip is one of the most popular products of Haomei Aluminum, it my turn to introduce the main product - transformer aluminum strip to you all. According to the use, the transformer aluminum strip can be divided into different grades, specifications and temper. The grades are: 1060,1050,1050A, 1060A,1070,1070A, 1350, the temper is O. O means of soft state, followed by the number that can show hard and soft, and the degree of annealing. The thickness is between 0.08-3.00 mm, known as: dry-type transformer aluminum strip.

AT ISSUE

There is a common misconception that a distribution transformer with copper windings is in some way more efficient, more reliable, or has higher short circuit strength when compared to a transformer with aluminum windings.

RECOMMENDATION

Improvements in technology regarding the use of aluminum in transformers have made aluminum-wound transformers the ideal choice for today’s applications.

RATIONALE

Operating Cost - Cooper Power Systems designs aluminum-wound transformers with windings of a larger cross-sectional area than would be used for a copper wound unit. This larger cross-sectional area translates to a lower current density, and an equivalent operating temperature. By reducing the current density in the windings, a low-loss design can be achieved with aluminum or copper windings.

Reliability - A transformer’s life is defined by the life of its insulation system. Because Cooper aluminum-wound and copper-wound units run at equivalent operating temperatures, the insulation systems age at the same rate for each design.

Lower Cost First - Whether low losses are the goal or not, aluminum windings are less expensive than copper windings. The following example shows two equivalent-loss designs, on with aluminum windings and one with copper windings.

ALUMINIUM STRIP FOR TRANSFORMER |

|||||||

Alloy/Temper |

1050-O, 1060-O, 1070-O,1350-O |

||||||

Thickness |

0.2-0.4 |

0.4-0.8 |

0.9-1.1 |

1.2-1.6 |

1.8-2.5 |

||

tolerance |

±0.01 |

±0.015 |

±0.02 |

±0.025 |

±0.03 |

||

Width |

<100 |

100-200 |

201-500 |

501-1250 |

>1250 |

||

tolerance |

±0.1 |

±0.2 |

±0.2 |

±1 |

±2 |

||

BURR AND COLLAPSE |

|||||||

The width of aluminium strip |

Burr's height |

Collapsed side's height |

|||||

<0.2 |

0.01 |

≥0.05-0.1 |

|||||

0.2-1.0 |

0.015 |

||||||

1.1-1.5 |

0.02 |

||||||

>1.6 |

0.03 |

||||||

MECHANICAL PROPERTY |

|||||||

U.T.S: 60-95N/mm2 |

Elongation: >25% |

||||||

Density in 20℃ :2.703kg/dm3 |

Max.resistance in 20℃:≤0.02825Ωmm2/m |

||||||

1350 aluminium strip for transformer winding can be used for variable transformer like low or high voltage transformer winding, high frequency transformer,step up or down voltage transformer ,distribution transformers ,etc.transformer aluminium strip for electrical coil application ranges from 0.3mm to 2.5mm, the alloy 1350 (99.50% aluminum) can be used to meet the minimum industry requirements for strip conductor, is closely controlled to assure smooth, substantially burr-free edges and strip-size availabilities are in capacities exactly equivalent to those of standard copper wire sizes.

1070 aluminium strip for transformer winding can be used for variable transformer like low or high voltage transformer winding, high frequency transformer,step up or down voltage transformer ,distribution transformers ,etc.transformer aluminium strip for electrical coil application ranges from 0.3mm to 2.5mm, the alloy 1070 (99.70% aluminum) can be used to meet the minimum industry requirements for strip conductor, is closely controlled to assure smooth, substantially burr-free edges and strip-size availabilities are in capacities exactly equivalent to those of standard copper wire sizes.

1060 aluminium strip for transformer winding can be used for variable transformer like low or high voltage transformer winding, high frequency transformer,step up or down voltage transformer etc.transformer aluminium strip for electrical coil application ranges from 0.3mm to 2.5mm, the alloy 1060 (99.60% aluminum) can be used to meet the minimum industry requirements for strip conductor, is closely controlled to assure smooth, substantially burr-free edges and strip-size availabilities are in capacities exactly equivalent to those of standard copper wire sizes.

1050 aluminium strip for transformer winding can be used for variable transformer like low or high voltage transformer winding,etc.transformer aluminium strip for electrical coil application ranges from 0.3mm to 2.5mm, the alloy 1050(99.50% aluminum) can be used to meet the minimum industry requirements for strip conductor, is closely controlled to assure smooth, substantially burr-free edges and strip-size availabilities are in capacities exactly equivalent to those of standard copper wire sizes.

Application

For more aluminum strip technical documents, Download free in PDF form !!